|

SPARTA PROJECT - Newsletter May 2021

SCRAP OF THERMOPLASTIC COMPOSITES MATERIALS

|

|

|

|

|

AIMPLAS starts research to develop more efficient methods of recycling composite materials

|

|

|

|

|

|

|

|

|

|

|

The aerospace industry is increasing its use of composite materials because of the advantages they offer in terms of weight reduction and strength. One of the drawbacks of these composite materials is the complexity of recycling them.

In response to this challenge, AIMPLAS is coordinating the SPARTA project, with the participation of TEKNIKER. Both centres will develop a new recycling method for key waste processing and reprocessing procedures. Specifically, TEKNIKER will contribute its knowledge and experience in mechanical cutting to the development and optimization of an innovative mechanical scrapping process, through simulation and experimentation, while AIMPLAS focuses on improving material reprocessing through automatic deposition and compression moulding. This method will make it possible to use up to 80% of current aerospace waste compared to other mechanical recycling methods, cut processing times as much as 50% by reducing the number of steps in waste recovery, use more efficient automatic reprocessing methods, reduce CO2 emissions up to 30% through the use of waste, and curb production demand for virgin material.

The result will be new, high-quality composite thermoplastic products manufactured with recycled materials at a production cost 15 to 20% lower than current mechanical recycling and scrap reprocessing procedures due to a reduction in the number of operations and automation of manufacturing processes. AIMPLAS will also be in charge of analysing the properties of the final product, as well as preparing a guide with eco-design recommendations for industrial scale-up of the process.

The project began this month and will end in October 2022. It has received funding from the EU Research and Innovation programme Horizon 2020 within the framework of the Clean Sky Joint Technology Initiative under grant agreement number 887073. This project is in line with SDG 12 on responsible consumption and production, SDG 13 on climate action, and SDG 9 on industry, innovation and infrastructure.

|

|

|

|

|

SPARTA Presents its poster and leaflet

|

|

|

|

|

|

|

|

|

The poster contains the main information about the project, while the leaflet contains information about the motivation of the project, its main goal and the approach taken by the project partners in order to achieve the goals stablished.

Both materials are now available for download at the SPARTA website.

|

|

|

SPARTA was presented at the clean sky 2 dissemination conference

|

|

|

|

|

|

|

|

|

|

|

As part of the Clean Sky 2 dissemination programme, Aernnova Aerospace SA and the Bioengineering and Aerospace Engineering department at the University Carlos III of Madrid (UC3M) have hosted an online conference on Wednesday 24 and Thursday 25 March 2021.

The event seeked contributions covering Clean Sky 2 research projects that are focused on the development of new materials, concepts and technologies that will reduce fuel consumption and maximise the efficiency of the next generation aircraft, in alignment with the Clean Sky 2 High Level Goals.

The technical scope covered both airframe and engines including research activities in aerodynamics, aerostructures, aircraft design, airframe and engine manufacturing, onboard systems, certification technology demonstrator development.

In the event, Rocío Ruíz Gallardo from AIMPLAS presented the SPARTA project, which is framed in the Airframe ITD Eco-Design Transverse Activity (TA) platform.

|

|

|

|

|

Radio Reto 16 Cimas interviews Rocío Ruíz about project SPARTA

|

|

|

|

|

|

|

|

|

The spanish radio programme "Círculo Verde" from Radio Reto 16 Cimas, interviews Rocío Ruíz about project SPARTA and the importance of reducing CO2 emissions in the transportation industry, especially in the aerospace sector.

Podcast available for download following the link: https://bit.ly/3ep0pte

|

|

|

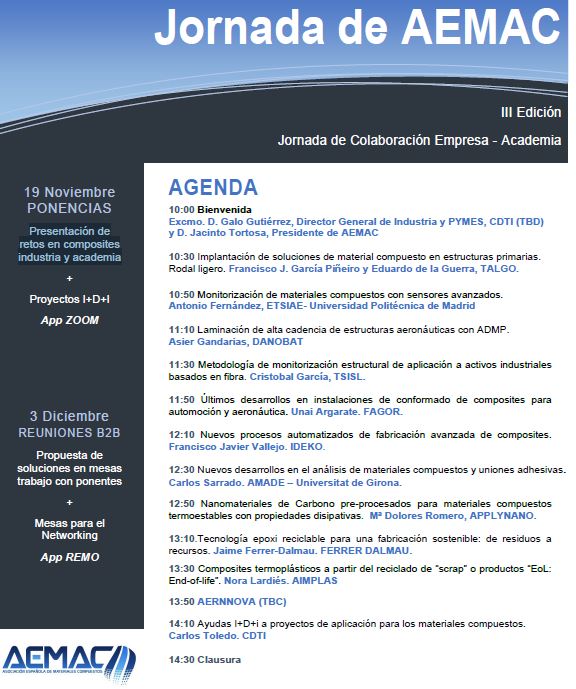

SPARTA participates in the AEMAC Seminar

|

|

|

|

|

|

|

|

|

SPARTA participates in the AEMAC Seminar "Challenges in composites" as a sponsor and with the presentation "Thermoplastic composites from scrap recycling or End-of-life products".

|

|

|

|

|

SPARTA arouses the interest of international media

|

|

|

|

|

|

|

|

|

|

|

Project SPARTA arouses the interest of international media. JEC Composites Magazine published the scientific article "A new generation of recycled composite materials for sustainable mobility" from Rocío Ruíz, Sustainable Mobility Researcher at AIMPLAS, leading AIMPLA`s activities within the SPARTA project.

In the article, Mrs. Ruíz states composite materials play a key role in the development of lightweight structures that help reduce vehicle weight. The main advantage of using more lightweight materials is the reduction in CO2 emissions. However, there are some drawbacks to using these materials, such as the large volume of waste generated during component manufacture, as well as during the incineration or landfill processes of the materials in the end-of-life stage (EoL).

Full article available for download.

|

|

|

|

|

Get to Know the partners of the SPARTA project

|

|

|

|

|

|

|

|

|

|

|

The AIMPLAS (project coordinator) and TEKNIKER research centres are carrying out this project in collaboration with Topic Manager Royal Netherlands Aerospace Centre (NLR). The SPARTA Project is framed within the Airframe ITD of the CS2 Programme. Its results will contribute to Europe’s strategic environmental and societal priorities while promoting the competitiveness and sustainable economic growth of the aeronautics industry.

About AIMPLAS

AIMPLAS, the Plastics Technology Centre, has a twofold mission: to provide added value to companies so they can create wealth and meet societal challenges to improve people’s quality of life and ensure environmental sustainability.

The institute also supports the 17 SDGs of the UN Global Compact when carrying out work and corporate social responsibility activities.

AIMPLAS is a non-profit research association and member of REDIT (Network of Technological Institutes of the Valencia Region) offering enterprises in the plastics industry comprehensive and customized solutions, including development and innovation projects, training, competitive and strategic intelligence, and technological services such as analysis, testing and technical assistance.

About Tekniker

Tekniker is a technology centre specialized in Advanced Manufacturing, Surface Engineering, Product Engineering and ICTs for manufacturing. Our mission is to bring growth and well-being through R&D&I to society as a whole, contributing in a sustainable way to the competitiveness of the business fabric.

This technology centre is a nonprofit foundation, member of the Basque Research and Technology Alliance, which has been created through a collaboration agreement between 16 technology centres and cooperative research centres belonging to the Basque Network of Science, Technology and Innovation, the Basque Government, the Councils of Araba, Bizkaia and Gipuzkoa and the SPRI Group.

|

|

|

|

|

|

|

|

|

|